RFID Jewelry Tracking System for Inventory Management in Retail Operations

Jewelry retail faces unique operational challenges. Jewelry items are high in value, small in size, and frequently handled across stores, display counters, and sales processes. An RFID jewelry tracking system provides a foundation for managing jewelry items at the individual piece level, delivering the accuracy, speed, and visibility that traditional manual inventory and barcode-based systems often struggle to achieve.

This guide explains how an RFID jewelry tracking system works, its benefits and applications, and why more retailers and manufacturers are adopting RFID jewelry management solutions to improve inventory accuracy and operational efficiency.

How Does an RFID Jewelry Tracking System Work?

An RFID jewelry tracking system is designed to manage high-value, small-sized jewelry items through item-level identification and real-time data capture.

In simple terms, the system works by attaching an RFID tag to each jewelry item. These RFID jewelry tags form the foundation of the tracking system by enabling item-level identification across inventory, display, and sales operations, while RFID hardware and software automatically identify, track, and manage items throughout daily store activities.

Commonly used hardware devices include:

- RFID printers

- RFID readers, including handheld devices and fixed readers installed inside display counters

- UHF RFID smart display trays for jewelry presentation and item detection

A typical retail RFID jewelry management system works as follows:

Item Identification

- Each jewelry item is assigned a unique RFID ID

- The ID is encoded and linked to product data such as style, material, weight, purity, and grade

RFID Encoding and Initialization

- RFID printers encode item IDs into RFID labels or tags

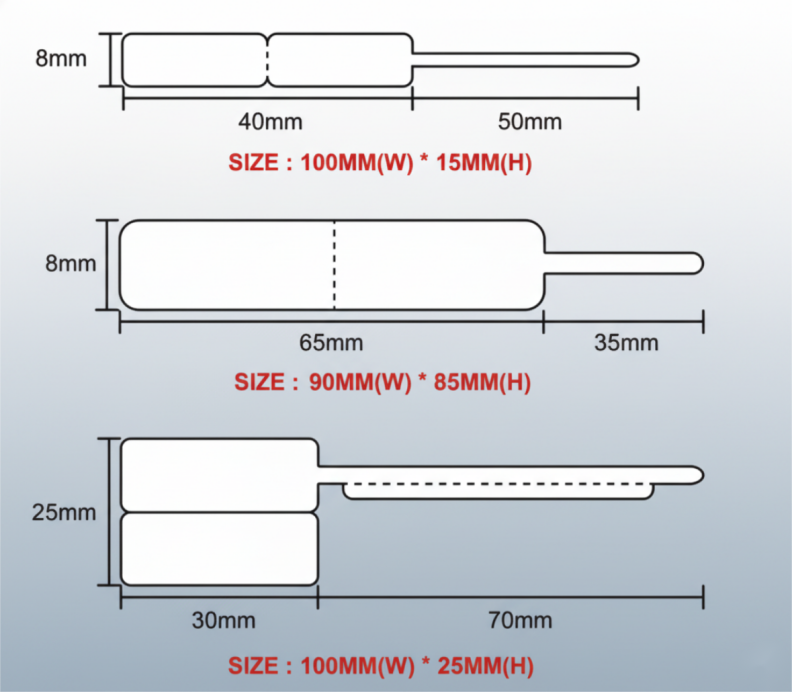

- RFID jewelry tags include folded tags, tail tags, and hang tags designed specifically for jewelry applications

- Printed human-readable text and barcodes allow dual RFID + visual identification

- Data consistency is ensured before items enter stores or display counters

Automated Data Capture

- RFID readers and handheld scanners read multiple jewelry items simultaneously

- No line-of-sight scanning is required, even in dense display environments

- Inventory data is collected in real time

System Integration

- Captured RFID data is processed by middleware

- Information is synchronized with ERP, inventory management systems, and POS platforms

- Item status (in stock, on display, transferred, sold) is updated automatically

By implementing this RFID jewelry tracking system, retailers can achieve the following:

- Inventory checks are reduced from hours to minutes

- Loss and misplacement risks are minimized

- Store staff can focus on customer service instead of manual counting

Benefits of Using RFID for Tracking Jewelry

Feature Comparison: Why Upgrade to RFID?

| Feature | Traditional Barcode System | RFID Jewelry Tracking System |

|---|---|---|

| Reading Method | Line-of-sight (Scan one by one) | Non-line-of-sight (Batch reading) |

| Inventory Speed | Hours (Slow & Laborious) | Minutes (Fast & Automated) |

| Accuracy | Prone to human error | 99.9% Data Accuracy |

| Security | Low (Barcodes can be photocopied) | High (Unique Chip ID) |

| Display Check | Requires removing items from tray | Scan whole tray instantly |

Compared with barcode-based systems, RFID is better suited for jewelry management because it eliminates manual, line-of-sight scanning and enables automatic item tracking throughout the entire lifecycle.

Item-level visibility for every jewelry piece

Each item carries a unique RFID ID that links product data and enables accurate tracking across inventory, display, and sales.

Non-line-of-sight and batch reading

Multiple jewelry items can be identified simultaneously without manual alignment, even inside trays or display counters.

Faster and more frequent inventory audits

Inventory checks are completed in minutes instead of hours, making daily or weekly audits practical.

Enhanced loss prevention and security monitoring

Real-time item visibility helps quickly detect missing or unauthorized movements in high-density display environments.

Lower operational pressure on store staff

Automated identification reduces manual counting and allows staff to focus on customer service and sales.

Applications of the RFID Jewelry Tracking System

Because of these advantages, RFID technology is widely applied across jewelry retail operations.

1. Inventory Counting: The Primary Use Case for Jewelry RFID

Inventory counting is the primary driver behind RFID jewelry inventory management adoption in retail environments.

Traditional manual counting is slow and labor-intensive due to the small size, high value, and dense display of jewelry items. In practice, a full store inventory often takes four to six hours, making frequent audits impractical and increasing the risk of unnoticed discrepancies.

With handheld RFID readers, inventory counting is reduced to minutes rather than hours. Staff can scan entire display trays without removing items, reading multiple pieces simultaneously and without line-of-sight. This enables daily or weekly inventory checks, improves stock accuracy, and significantly reduces operational pressure on store personnel.

2. Sales and Checkout Confirmation: Ensuring Item Accuracy at the Point of Sale

At the checkout stage, RFID helps eliminate identification errors that can occur with manual selection or barcode scanning.

By verifying each jewelry item's RFID ID at the POS counter, the system confirms the correct item before completing the transaction.

Once sold, the item's status is automatically updated in the system, creating a clear and auditable sales record. This improves transaction accuracy, reduces reconciliation issues, and provides better control over high-value inventory during the final step of the sales process.

In addition to inventory counting and sales confirmation, RFID technology is also applied to support several day-to-day operational scenarios in jewelry retail:

Display counter monitoring

Fixed RFID readers and UHF smart display trays detect the presence of tagged items on display counters, helping reduce loss risk in high-traffic or open display environments.

Internal transfers & handovers

RFID scanning records item movement between counters, stores, or repair processes with clear accountability.

Smart product presentation

RFID-enabled displays retrieve item-specific information from backend systems-such as style, material, weight, and purity-when a tagged product is presented, assisting sales staff during customer interactions.

Best Practices for Deploying RFID Jewelry Tracking Solutions

A successful RFID jewelry tracking solution depends on three things: consistent encoding rules, reliable hardware, and repeatable store workflows.

Standardize your item ID/EPC rules

Define one encoding format across HQ + stores to avoid duplicate IDs and data mismatches.

Encode + verify before items hit the counter

Ensure every tag is written correctly and matches the ERP/IMS record before display.

Use the right reader setup

Handheld readers for audits; fixed readers (in-counter) for monitoring and checkout points.

Recommended RFID Printer for Jewelry Tracking: iDPRT iT4R Series

For jewelry RFID projects, the primary challenge is to produce sharp, scannable barcode labels while creating a reliable digital identity for each high-value item.

The iDPRT iT4R series is a 4-inch desktop RFID printer that combines RFID encoding, verification, and label printing into a single, streamlined workflow, well suited for jewelry deployments.

The RFID tag printer accurately encodes RFID data into the tag's memory using UHF RFID technology, enabling each jewelry item to be uniquely identified and digitally managed. When integrated with RFID readers and backend systems, this supports fast inventory checks, real-time tracking, and system-driven sales management across jewelry retail operations.

Features:

Supports Multiple Jewelry RFID Tag Types and Sizes

Handles compact RFID jewelry tags-including rat-tail, loop, and folded tags-in various sizes, suitable for rings, necklaces, bracelets, and other small, high-value jewelry items.

Precise Encoding with Anti-Metal Capability for UHF RFID Jewelry Tags

Jewelry environments are full of metal and liquids that interfere with RFID signals. The iT4R features advanced antenna positioning and automatic calibration to ensure successful encoding even on small, interference-prone UHF RFID jewelry tags.

Built-in Write & Verify for 100% Readability

The built-in write-and-verify process flags defective tags during printing to reduce read errors in inventory and checkout operations.

300dpi High-Resolution Barcode Printing

Prints clear, high-resolution barcodes while encoding EPC data at the same time, supporting reliable scanning at jewelry counters and checkout points.

Touch Display for Intuitive Store-Level Operation

An integrated LCD touch screen supports offline workflows and allows store staff to perform on-demand tag replacement or reprinting without complex setup.

Easy to integrate with existing systems

Works smoothly with ERP, POS, and RFID management software, supporting both centralized initialization and distributed store operations.

Partner with Us

For retailers planning an RFID jewelry tracking solution, choosing the right hardware is a critical first step.

As a leading AIDC solution provider in China, iDPRT offers RFID printers and handheld RFID readers designed to support fast inventory counting and reliable item verification in jewelry retail environments. Our RFID devices provide a solid foundation for item-level tagging, encoding, and daily inventory operations.

For businesses planning or expanding RFID deployments, we welcome you to contact iDPRT to discuss tailored RFID hardware solutions for jewelry management applications.

Future Trends in RFID Jewelry Tracking Technology

As RFID adoption in the jewelry industry matures, the focus is shifting from basic deployment toward standardization and scalability. More brands are establishing unified item-level identification and EPC encoding rules across manufacturing, logistics, and retail stores, reducing data inconsistency and enabling RFID systems to scale more smoothly across multi-store or regional networks.

At the same time, RFID is becoming more deeply integrated with POS, ERP, and inventory management platforms. Rather than serving only as a tool for inventory counting, RFID data is increasingly used to support real-time stock visibility, sales confirmation, and exception management, helping retailers move from periodic audits to continuous operational control.

On the hardware side, RFID tags, printers, and readers are evolving to better suit jewelry-specific environments, with improved stability near metal and simpler store-level operation.

Together, these developments position RFID not as a standalone technology, but as a long-term infrastructure for accurate, scalable, and data-driven jewelry management.

Frequently Asked Questions About RFID Jewelry Tracking Systems

Q1 Can RFID tags fit on small items like rings and earrings?

Yes. Specialized UHF RFID tags (such as "rat-tail" or loop tags) are designed specifically for jewelry. They are compact enough to attach to small, delicate items like rings and studs without affecting aesthetics or customer trial.

Q2 Does RFID replace barcodes in jewelry management?

Not entirely. In most deployments, RFID and barcodes are used together - RFID for fast, non-line-of-sight identification, and barcodes or human-readable text for visual verification and system compatibility.

Q3 How fast is inventory counting with RFID?

RFID enables batch reading, allowing hundreds of items to be scanned in minutes and reducing inventory counting time by over 90%.

Q4 Can RFID integrate with my existing POS and ERP?

Yes. Professional RFID jewelry solutions use APIs and middleware to sync seamlessly with major retail management systems (such as Microsoft Dynamics, SAP, or Oracle). This ensures that sales and stock levels are updated in real-time across all platforms.

Q5 Is RFID practical for small or single-store jewelry businesses?

Yes. With entry-level handheld readers and simplified encoding processes, small jewelry stores can start with RFID inventory counting and expand usage as needed.